Project Description

Features

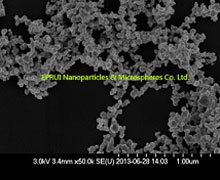

Copper has good conductive properties. After being processed into the nanoparticles, copper nanoparticles no longer have conductive properties, but with other superior performance, such as antibacterial, deodorant, catalysis, lubrication.

Specification

| Item | Purity | APS | SSA | Color | Morphology | Making Method |

|---|---|---|---|---|---|---|

| Nano Copper | 99.9%+ | ≤50nm | >20m2/g | Dark Red | spherical | Physical Method |

| Nano Copper | 99.9%+ | ≤100nm | >16m2/g | Dark Red | spherical | Physical Method |

| Copper Micropowder | 99.9%+ | 180nm | >1.5m2/g | Dark Red | spherical | Physical Method |

| Copper Micropowder | 99.9%+ | 300nm | >1.5m2/g | Black | spherical | Physical Method |

Applications

- Cu Nanoparticles used in conductive coatings; conductive inks; Conductive slurry: The copper nanopowder can be applied to the production of MLCC internal electrode and other electronic components in electronic slurry for the miniaturization of microelectronic devices; The electronic size with good performance made of copper nanopowder instead of valuable metal particles cuts cost to a large extent; This technology is used to the preference of microelectronic processes; Conductive pastes; Cu Nanoparticles are high thermal conductivity materials

- Ideal Lubricant additives: Adding 0.1~0.6% of copper nanopowder to lubricant oil and lubricant grease. It will form a self-lubricating and self-repairing coating film in the frictioning surface and lower its anti-friction and anti-wear performance; Cu Nanoparticles Lubricants additives; Cu Nanoparticles Sintering additives

- Medicine append material; Capacitor materials

- Raw material for bulk nanomaterial: Adopt the inert gas to make bulk copper nano composite material with powder metallurgy

- Cu Nanoparticles is widelly used as Catalysts; Efficacious catalyst: Copper and copper alloy nanometer, feature high efficacy and selectivity, can be used as catalyst in some reactions, e.g. carbon dioxide compound hydrogen to produce methanol

- The superficial conductive coating processing of metal and non-ferrous metal

Storage Conditions

Damp reunion will affect its dispersion performance and using effects, therefore, this product should be sealed in vacuum and stored in cool and dry room and it should not be exposure to air. In addition, the Copper (Cu) Nanoparticles should be avoided under stress.

Cautions

- Metal nanoparticles should be gently placed and avoided violent vibration and friction

- Metal nanopowder should be prevented from moisture, heat, impact and sunlight

- The user must be a professional (This person must know how to use this product.)