Project Description

Applications

Metal machining additives, adding 1-4% nano Mo powder to stainless steel can make stainless steel improve anticorrosive capability in corrosive environments; Electron industry, mainly used in making high-power vacuum valve, heater tube, X-Ray tube, and so on; Wood machining. Catalysts; Coatings; Cutting tools; Hard alloys; High-temperature lubrication; Microelectronics films;Sintering additives

Specification

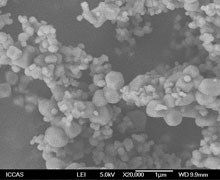

| Item | Purity | APS | SSA | Color | Morphology | Bulk Density |

|---|---|---|---|---|---|---|

| Molybdenum Nanoparticle | 99.90% | 30-80nm | 8-12 m2/g | Black | Spherical | 0.24 g/cm3 |

Storage Conditions

Damp reunion will affect its dispersion performance and using effects, therefore, Mo Nanoparticle should be sealed in vacuum and stored in cool and dry room and it should not be exposure to air. In addition, Molybdenum Nanoparticles should be avoided under stress.

Cautions

- Molybdenum nanoparticle is flammable. It should be gently placed and avoided violent vibration and friction.

- Molybdenum Nanoparticle should be prevented from moisture, heat, impact and sunlight.

- The user must be a professional (This person must know how to use Molybdenum Mo Nanoparticle.)